Sorting Machines

The benefits of automated sorting are obvious. With a sorting machine, you save costs and make your logistics process faster, better, and error-free (= fewer returns). But which sorting machine is right for your company? We’ll answer that question shortly—let’s start at the beginning.

What does a sorting machine do?

A sorting machine automatically sorts products based on pre-set criteria (WMS). This could be: orders, color, type, quantities, addresses, etc. Depending on the type of sorter and the product (size, weight, shape), processing ranges from 3,000 to 25,000 items per hour. And in most cases, hardly any human hands are involved.

Automatic sorting can be multi-flow: inbound, outbound, and returns. Incoming goods can be counted and sorted for the warehouse. Outgoing goods are sorted by order, and returns are sorted by destination (warehouse, order, or alternative destination).

Which sorter is best for your company?

First of all, there is no one-size-fits-all. There are different sorting machine systems. Some sorters are better for fashion, others for 3PL, e-commerce, or books. The experts at DistriSort are happy to help you make the best choice—or use our product selector below in just 4 clicks.

Types of sorting machines

To help you get started, here are the three most commonly used types of sorting machines:

- Split Tray sorter

- Push Tray sorter

- Cross Tray sorter

Ad 1. Split Tray sorter

The Split Tray comes in two versions: the Single Split Tray and the Dual Split Tray. The difference lies in the carriers. The drop mechanism consists of two or four equal sections. Items drop straight down, allowing for direct stacking into a crate or box. Loose items stay neatly in place.

Suitable for sorting: clothing, mail (mixed and residual), books/magazines.

- Capacity Single Split Tray: 3.000 to 17.280 trays/hours

- Capacity Dual Split Tray: 8.000 to 34.560 trays/hours

Ad 2. Push Tray sorter

The Push Tray is a sorter with a two-sided discharge system. This means double the number of exits (left and right) within a small footprint. DistriSort offers two versions: the Single Push Tray and the Twin Push Tray. Each tray has one or two sliders between two raised edges. By moving the slider to the left or right, items are automatically discharged into a pre-set exit.

Ideal for sorting: shoes, sporting goods, and toys.

- Capacity Single Push Tray: 3.000 to 16.000 trays/hours

- Capacity Twin Push Tray: 7.000 to 24.000 trays/hours

Ad 3. Cross Tray sorter

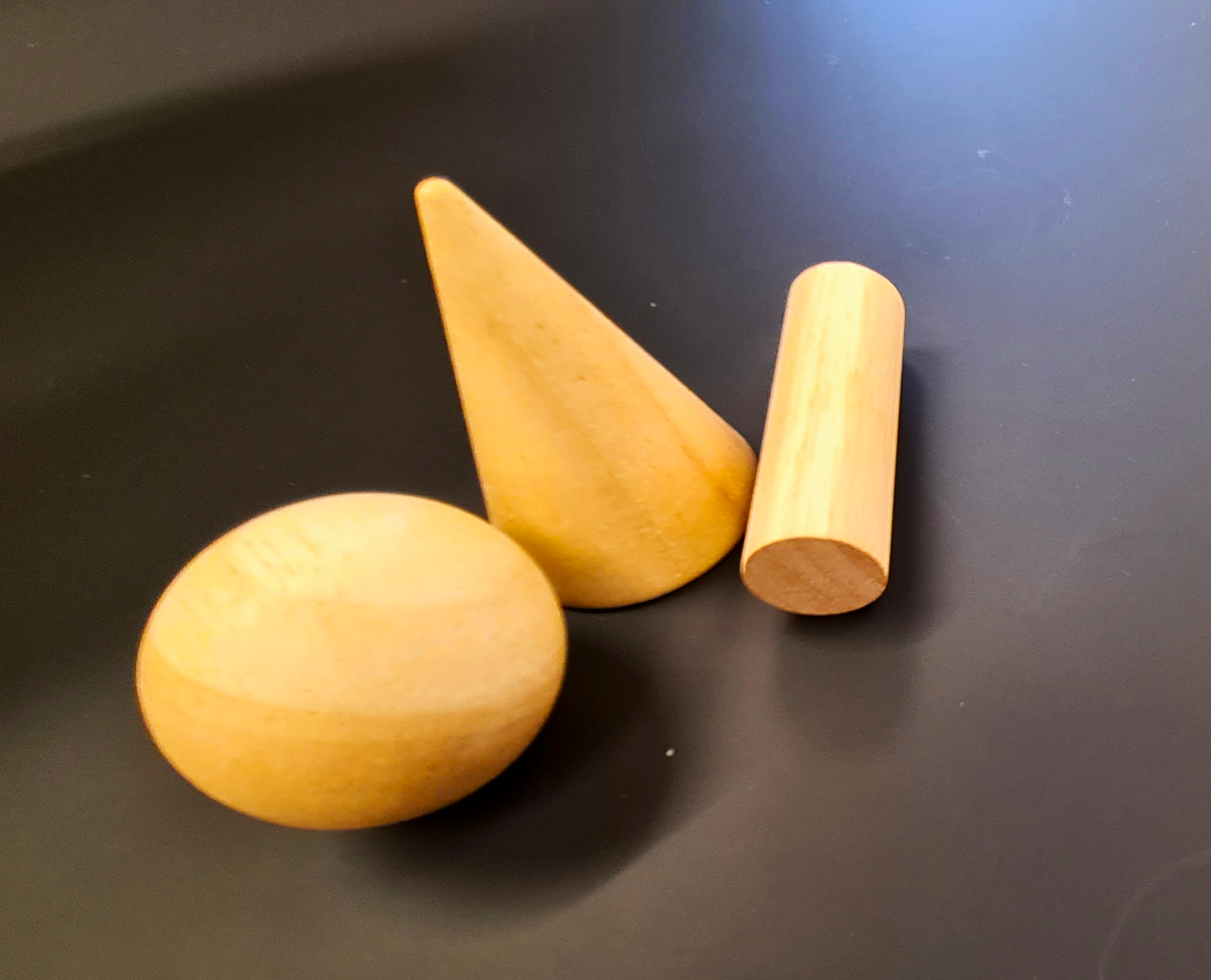

The Cross Tray is a true all-rounder. With four raised edges, it is ideal for sorting unstable items (round, cylindrical, conical, etc.)—packages that wouldn’t stay in place on a cross belt system.

Ideal for sorting: automotive spare parts, jewelry and watches, accessories, medicines and supplements, parcels, consumer goods, drugstore items, multimedia, and small electronics.

There is also the Cross Tray XL for larger packages—especially interesting for 3PL providers and parcel & post companies.

- Capacity Cross Tray: 3.000 to 17.000 trays/hours

- Capacity Cross Tray XL : 3.000 to 15.000 trays/hours

The sorting machines provided by DistriSort

As a system integrator, DistriSort is responsible for the quality of the sorters and peripheral equipment we install. We work with a fixed supplier for sorting machines: EuroSort.

EuroSort machines have a proven track record in various industries worldwide—reliable technology and excellent service.

Our sorting machines are highly suitable for:

- Multi-flow sorting: inbound, outbound & returns on one machine

- Sorting unusual shapes: ball, cylinder, egg-shaped, conical, etc.

- E-commerce: many loose items, high speed, error-free sorting

- Fashion & retail: many loose items, store replenishment, and return handling

- Post & parcels: high volumes, varied product mix, compact footprint

- 3PL: scalability (demand/supply), multi-client setup

- Pharmaceuticals & cosmetics: precision, small and light items, traceability

- Books: damage-sensitive, high volumes, stackable

Our sorting machines are less/not suitable for:

- Low volumes (< 2.500 UPH)

- Extremely large formats

- Food products

FAQ Sorting Machines

See below for the most frequently asked questions about sorting machines. If your question isn’t (yet) listed, feel free to contact us. Our experts are happy to assist you.

A sorting system is an integral part of the logistics process, taking into account the existing and desired variables that play a role within it. A sorting machine is a standalone unit that forms part of an existing or newly designed system.

Yes. DistriSort has its own software development company, where tailor-made software solutions are created. All our sorting solutions can be seamlessly integrated with any WMS

Daily maintenance is minimal and can be performed by operators where necessary—such as keeping sensors dust-free. Even replacing a carrier is a do-it-yourself level task. DistriSort has its own dedicated service department. An annual check-up is recommended, and for major maintenance, an invitation is sent well in advance.

The Split Tray Sorter or Dual Split Tray Sorter is highly suitable for smaller products, such as jewelry, medicines, small electronics, clothing, or residual mail.

An automatic sorting machine sorts with 99.9% accuracy. The sorter itself does not make mistakes—any error is always due to the barcode or RFID.

Yes, both. DistriSort has its own Innovation Center, where a Split Tray Sorter, a Push Tray Sorter, and a Cross Tray Sorter are available in a demo setup. By arrangement, customers can bring their products to be sorted, either live or via video.